Yc-8101a Porcelain Nano-composite Ceramic Coating inodziya zvakanyanya (Nhema)

Zvikamu zvechigadzirwa uye chitarisiko

(Kuputira kweceramic kune zvikamu zviviri)

YC-8101A-A:Kuputira kwechikamu A

YC-8101A-B: Mushonga wekurapa wechikamu cheB

YC-8101 mavara:zvinoonekera, zvitsvuku, yero, bhuruu, chena, nezvimwewo. Kugadziriswa kwemavara kunogona kuitwa zvichienderana nezvinodiwa nevatengi

Substrate inoshanda

Nzvimbo dzezvinhu zvakasiyana-siyana zvakaita semapani asinganamatire dzinogona kugadzirwa nesimbi, simbi yakapfava, simbi yekabhoni, simbi isingatsvedzeri, aruminiyamu, titanium alloy, simbi yemhando yepamusoro, girazi re microcrystalline, ceramics, nezvimwe zvinhu.

Tembiricha inoshanda

- Kudzivirira kupisa kwakanyanya i800℃, uye tembiricha yekushanda kwenguva refu iri mukati me600℃. Haigoni kukanganiswa nekukukurwa kwemvura zvakananga nemoto kana kuyerera kwegasi rinopisa zvakanyanya.

- Kuramba kupisa kwejira repurasitiki kunosiyana zvichienderana nekuramba kupisa kwezvikamu zvakasiyana. Kuramba kutonhora, kupisa, uye kudengenyeka kwekupisa.

Zvimiro zvechigadzirwa

- 1. Nano-coatings dzinobva mumvura chete, dzakachengeteka, dzine hushamwari kune nharaunda uye hadzina chepfu.

- 2. Zviumbwa zveNano-composite zvinoita kuti zviome uye zviite sezvisina kusimba patembiricha yakaderera ye250℃, izvo zvinochengetedza simba uye zvinofadza runako.

- 3. Kuramba kwemakemikari: Kuramba kupisa, kuramba acid, kuramba alkali, kudzivirira kupisa, kuramba kupisa kwakanyanya, uye kuramba zvigadzirwa zvemakemikari, nezvimwewo.

- 4. Kuputira uku hakupindi tembiricha yepamusoro uye kupisa mukati mehukobvu hwakati (anenge ma microns makumi matatu), uye kunodzivirira kupisa kwakanyanya (kunopesana nekupisa, uye hakutsemuki kana kubvaruka mukati mehupenyu hwekushanda kwepurasitiki).

- 5. Kuputira kwe nano-inorganic kwakakora uye kune simba remagetsi rakagadzikana rekudzivirira, uye kuputira kunodzivirira kunokwanisa kumira volteji inosvika chiuru chimwe chete.

- 6. Ine simba rekupisa rakagadzikana uye rakanaka uye ine simba rakanaka rekubatanidza.

- 7. Kuoma: 9H, inodzivirira moto wakavhurika uye tembiricha yepamusoro inosvika 400 degrees, kupenya kwakanyanya, uye kuramba kupfeka kwakanyanya

Minda yekunyorera

1. Zvikamu zvebhoyira, mapaipi, mavharuvhu, zvinochinja-chinja kupisa, maredhiyeta;

2. Girazi re microcrystalline, zvishandiso nemidziyo, zvishandiso zvekurapa, michina yemishonga, uye michina yemajini ehupenyu;

3. Midziyo inodziya zvakanyanya uye zvikamu zve sensor inodziya zvakanyanya;

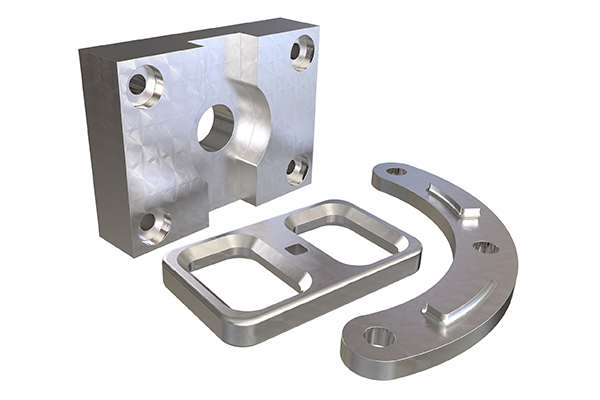

4. Pamusoro pemidziyo yesimbi, mapundu, uye michina yekukanda;

5. Zvinhu zvemagetsi zvinodziya, matangi, nemabhokisi;

6. Midziyo midiki yemumba, midziyo yekubikira, nezvimwewo.

7. Zvikamu zvinopisa zvakanyanya zvemaindasitiri emakemikari nesimbi.

Nzira yekushandisa

(Kuti uve nechokwadi chemhedzisiro yakanaka, zvinokurudzirwa kuishandisa nenzira inotevera)

1. Zvikamu zviviri:Vhara wobva wapukuta nechiyero chehuremu hwe2:1 kwemaawa maviri kusvika matatu. Pendi yakacheneswa inozoseferwa nepahwindo remasefa re400-mesh. Pendi yakaseferwa inova pendi yeceramic yakagadzirwa uye inoiswa padivi kuti ishandiswe gare gare. Pendi yekuwedzera inofanira kushandiswa mukati memaawa makumi maviri nemana; zvikasadaro, mashandiro ayo achadzikira kana kuoma.

2. Kuchenesa zvinhu zvepasi:Kubvisa mafuta nengura, kukwesha pamusoro pevhu uye kuputira jecha, kuputira jecha neSa2.5 grade kana kupfuura, mhedzisiro yakanakisisa inowanikwa nekuputika jecha ne46-mesh corundum (white corundum).

3. Kupisa kwekubikira: 270℃ kwemaminitsi makumi matatu (Inogona kurapwa patembiricha yemumba. Kushanda kwekutanga kwakashata zvishoma, asi inogona kudzokera kune yakajairika nekufamba kwenguva.)

4. Nzira yekuvaka. Kupfapfaidza:Chishandiso chekupfapfaidza chinofanira kupiswa kusvika pa40℃ chisati chapfapfaidza; zvikasadaro, zvinogona kudonha kana kuderera. Zvinokurudzirwa kuti ukobvu hwekupfapfaidza huve mukati mema microns makumi matatu. Chinogona kupfapfaidzwa kamwe chete.

5. Kurapa kwezvishandiso zvekuputira uye kurapwa kwekuputira

Kubata maturusi ekuputira: Chenesa zvakanaka neanhydrous ethanol, omesa nemhepo yakamanikidzwa wochengeta.

6. Kurapa kwekuputira: Mushure mekupfapfaidza, rega iome pachayo pamusoro pemvura kwemaminitsi angangoita makumi matatu. Wobva waiisa muovheni yakapiswa pa250 degrees woichengeta ichidziya kwemaminitsi makumi matatu. Kana yatonhorera, ibudise.

Yakasarudzika kuna Youcai

1. Kugadzikana kwehunyanzvi

Mushure mekuyedzwa kwakasimba, maitiro e tekinoroji ye nanocomposite ceramic aerospace-grade anoramba akagadzikana mumamiriro ezvinhu akaoma, anodzivirira kupisa kwakanyanya, kupisa kwakanyanya uye ngura yemakemikari.

2. Tekinoroji yekupararira kweNano

Maitiro akasiyana ekupararira anoita kuti zvimedu zvidiki zviparadzirwe zvakaenzana mujira, zvichidzivirira kusangana. Kugadzirisa mashandisirwo azvo kunowedzera kubatana pakati pezvikamu, zvichivandudza simba rekubatana pakati pejira nejira pamwe nekushanda kwaro kwese.

3. Kugona kudzora kupeta

Mafomu akanyatsogadzirwa uye matekiniki akagadzirwa zvinogonesa kuti magadzirirwo ejira rekuputira agadziriswe, akadai sekuomarara, kuramba kupfeka uye kugadzikana kwekupisa, zvichizadzisa zvinodiwa zvemashandisirwo akasiyana.

4. Hunhu hwechimiro che micro-nano:

Zvidimbu zvesimbi zvenanocomposite zvinoputira zvidimbu zve micrometer, zvozadza mipata, zvoumba coating yakakora, uye zvinosimudzira kusimba uye kuramba ngura. Panguva iyi, zvidimbu zvesimbi zvinopinda pamusoro pe substrate, zvichigadzira interphase yesimbi-ceramic, iyo inowedzera simba rekubatanidza uye simba rose.

Nheyo yekutsvagisa nekusimudzira

1. Dambudziko rekufananidza kuwedzera kwekupisa:Ma coefficients ekuwedzera kwekupisa kwezvinhu zvesimbi nezvinhu zveceramic anowanzosiyana panguva yekupisa nekutonhodza. Izvi zvinogona kutungamira pakuumbwa kwema microcracks mu coating panguva yekuchinja kwekupisa, kana kutobvaruka. Kuti agadzirise dambudziko iri, Youcai akagadzira zvinhu zvitsva zvekuputira zvine coefficient yekuwedzera kwekupisa iri pedyo neiyo ye substrate yesimbi, nokudaro zvichideredza kushushikana kwekupisa.

2. Kuramba kupisa kunotyisa uye kupisa kuzununguka: Kana simbi ichichinja-chinja tembiricha yepamusoro neyakaderera, inofanira kukwanisa kutsungirira kupisa kunokonzerwa nekukasira pasina kukuvara. Izvi zvinoda kuti simbi iyi ive nekudzivirira kupisa kwakanyanya. Nekugadzirisa magadzirirwo e microstructure e simbi, zvakaita sekuwedzera huwandu hwe phase interfaces uye kuderedza saizi ye grain, Youcai inogona kuwedzera kudzivirira kupisa kwayo.

3. Simba rekubatana: Simba rekubatanidza pakati pejira nesimbi rakakosha kuti jasi rigare kwenguva refu uye rigare kwenguva refu. Kuti uwedzere simba rekubatanidza, Youcai anounza jira repakati kana kuti jira rekuchinja pakati pejasi nesimbi kuti awedzere kunyorova uye kubatana kwemakemikari pakati pezviviri.